COOK valves for reciprocating compressors

Cook Compression is an innovator in the design, manufacture and application of compressor valves. From precision-crafted metal plate valves to the latest high-performance designs with non-metallic internals, we offer solutions for any reciprocating compressor in any type of service.

Cook Compression manufactures complete valve assemblies, as well as plates, discs, rings, buttons, poppets, damper plates, spring plates, leaf springs and other metallic and non-metallic components for any make or model valve.

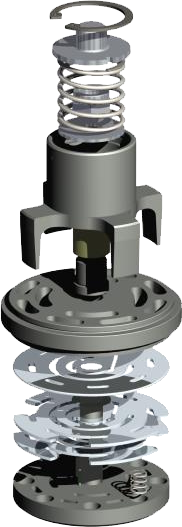

Optima Series

Standard plate valve for reciprocating compressors |

Manley Valve

Premium ring valve for refining/storage & high pressure applications |

Ring Damped Valve High efficiency, superior reliability valves for high speed NG compressors |

Moppet Valve

Premium high durability valve for high pressure, dirty gases/liquids |

Valve Portofolio

|

|

|

|

|

|

1200 rpm

900 rpm

600 rpm

300 rpm |

Ring Damped Valve

Optima Series

|

Manley Valve

Moppet Valve |

Metallic Optima Plate Valve

|

Natural Gas

|

Process

|

Air

|

We can deliver complete BEKOMAT electronically level-controlled condensate drains and service kits as well. The BEKOMAT range provides the 12, 13, 14 and 16 standard drains for virtually every application, which are not just the correct solution, rather more also the most suitable low-energy solution. The integrated capacitive sensor for level-controlled condensate discharge helps save energy and enhances efficiency – which is what you would expect from a BEKOMAT.

We can deliver complete BEKOMAT electronically level-controlled condensate drains and service kits as well. The BEKOMAT range provides the 12, 13, 14 and 16 standard drains for virtually every application, which are not just the correct solution, rather more also the most suitable low-energy solution. The integrated capacitive sensor for level-controlled condensate discharge helps save energy and enhances efficiency – which is what you would expect from a BEKOMAT. The regular maintenance was carried out in 2 consecutive years by the team of TUNGS-STAR on an ABC Horizon 1400 compressor at Plastipak Romania SRL in Urlati. The 40 bar PET compressor is powered by a 280 kW motor equipped with VSD. It has 3 stages with 4 horizontally opposed cylinders.

The regular maintenance was carried out in 2 consecutive years by the team of TUNGS-STAR on an ABC Horizon 1400 compressor at Plastipak Romania SRL in Urlati. The 40 bar PET compressor is powered by a 280 kW motor equipped with VSD. It has 3 stages with 4 horizontally opposed cylinders. New 15 kW MATTEI compressor was installed next to an old 7.5 kW Mattei compressor to assure the increased production of a local company.

New 15 kW MATTEI compressor was installed next to an old 7.5 kW Mattei compressor to assure the increased production of a local company.